Safety sensor recalibration is a crucial process for maintaining the reliability and performance of autonomous systems, ADAS (Advanced Driver Assistance Systems), and auto painting applications by addressing malfunctions due to wear, environmental factors, or improper setup. Technicians use specialized tools to identify issues like offset measurements and sensitivity variations in sensors, ensuring accurate collision detection and optimal functionality. Regular tire services, as part of car damage repair, help prevent sensor misalignment, contributing to long-term cost-effective vehicle maintenance and bolstering safety. Proactive diagnostic tools and integrated assessments, commonly employed in tire services and collision centers, enable early detection of problems, promoting road safety and vehicle longevity.

In the realm of industrial safety, regular safety sensor recalibration is paramount to ensure life-saving systems function optimally. However, this process isn’t without its challenges. This article delves into the common issues encountered during safety sensor recalibration services, shedding light on malfunctioning sensors, environmental factors, and the unique challenges posed by technological advancements. By understanding these intricacies, facilities can enhance their safety protocols and mitigate potential risks associated with inaccurate sensor readings.

- Identifying Malfunctions and Errors

- – Common types of sensor malfunctions

- – How to diagnose issues using diagnostic tools

Identifying Malfunctions and Errors

When conducting safety sensor recalibration services, technicians often encounter various malfunctions and errors that require careful attention. These issues can stem from a multitude of factors, including sensor wear and tear, environmental influences, or improper initial setup. During the recalibration process, specialized tools are used to assess the sensor’s performance and identify any discrepancies in its readings. By comparing these results with established standards, technicians can pinpoint exact problems, such as offset measurements, sensitivity variations, or even complete sensor failure.

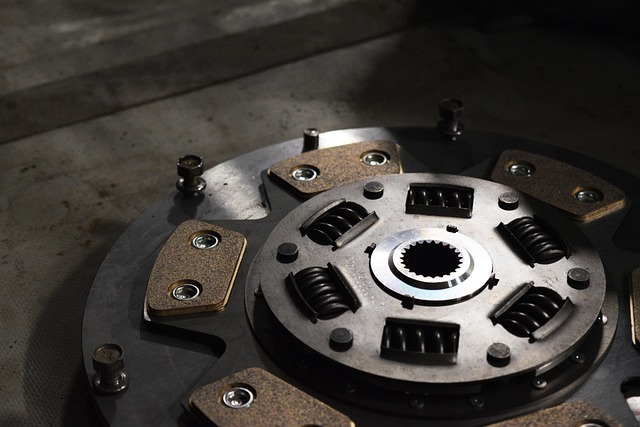

Proper identification of these malfunctions is crucial for ensuring the safety and reliability of autonomous systems or advanced driver-assistance systems (ADAS). For instance, misaligned sensors could lead to inaccurate collision detection, impacting the overall performance of car body repair and damage restoration processes. In such cases, technicians must employ precise techniques, including detailed inspections and adjustments, to resolve these errors and ensure optimal sensor functionality for auto painting applications.

– Common types of sensor malfunctions

Safety sensor recalibration is a critical process aimed at ensuring optimal performance and reliability of safety systems in vehicles. Common types of sensor malfunctions that surface during this service include misalignment, sensitivity drift, and signal interference. Misalignment occurs when sensors fail to accurately detect objects or obstacles due to improper positioning or calibration. Sensitivity drift happens over time as sensors lose their initial responsiveness, leading to false readings or missed detections. Signal interference, on the other hand, arises from external factors like electromagnetic pulses, radio frequency noise, or even nearby operating machinery, causing erratic sensor behavior.

Regular vehicle repair and maintenance can help prevent these issues by addressing potential problems early on. Tire services, as part of overall car damage repair, play a significant role in ensuring tires are properly inflated and aligned, reducing the chances of sensor misalignment. Proactive measures such as these not only enhance safety but also contribute to cost-effective vehicle maintenance over time.

– How to diagnose issues using diagnostic tools

Diagnosing issues during safety sensor recalibration is a meticulous process that relies heavily on advanced diagnostic tools. These tools, often integrated into modern vehicle systems, provide real-time data and insights into sensor performance. By analyzing data from various sensors—including accelerometers, gyroscopes, and speed sensors—technicians can identify discrepancies or anomalies indicative of potential problems. For instance, a tire service or collision center might employ diagnostic software to check for sensor drift, misalignment, or malfunctioning components. This proactive approach ensures that any issues are detected early, preventing potentially hazardous situations on the road.

Furthermore, leveraging these tools allows for comprehensive checks beyond the safety sensors themselves. Related services like car dent repair, while not directly related to sensor recalibration, can offer insights into overall vehicle condition. For example, a dent or damage in certain areas might influence sensor readings, highlighting the need for holistic vehicle assessments during maintenance routines. This integrated approach ensures that all components work harmoniously, enhancing road safety and vehicle longevity.

Safety sensor recalibration is a critical process that ensures optimal performance in various industrial settings. By understanding common issues and employing effective diagnostic tools, professionals can efficiently navigate potential malfunctions. Regular maintenance and timely intervention through recalibration services contribute to enhanced system reliability, ultimately improving overall safety measures.