Safety sensor recalibration is essential for modern vehicles' advanced driver assistance systems (ADAS), ensuring optimal performance and reliability throughout their lifespans. Regular calibration addresses sensor drift from environmental factors, wear, or damage, maintaining safety feature integrity after repairs. This meticulous process uses specialized tools to simulate real-world conditions, calibrating sensors according to OEM specifications for accurate data input during emergencies. Proactive recalibration prevents hazards and costly repairs, ensuring vehicle safety features meet the highest industry standards.

Safety sensors are vital components in modern machinery, ensuring operational efficiency and worker safety. This article delves into the critical process of safety sensor recalibration, aligning with Original Equipment Manufacturer (OEM) specifications. We explore the significance of understanding OEM standards, the step-by-step recalibration process for optimal performance, and the need for regular calibration checks to maintain accuracy. By adhering to these guidelines, manufacturers can ensure their safety sensors function at peak levels, enhancing overall system reliability.

- Understanding OEM Safety Sensor Standards

- Process of Recalibration for Optimal Performance

- Ensuring Accuracy: Regular Calibration Checks

Understanding OEM Safety Sensor Standards

Original Equipment Manufacturer (OEM) safety sensors are integral components of modern vehicles, designed to ensure the well-being of passengers and other road users. These sensors play a critical role in advanced driver assistance systems (ADAS), such as automatic emergency braking, lane departure warning, and adaptive cruise control. Understanding and adhering to OEM standards for safety sensor recalibration is essential to guarantee these systems’ optimal performance and reliability.

OEM specifications provide detailed guidelines on how often sensors should be calibrated, the conditions under which recalibration is required, and the methods to ensure precise adjustments. Recalibration ensures that sensors remain accurate and responsive over the vehicle’s lifespan, accounting for potential drifts in sensitivity due to environmental factors, wear and tear, or after certain types of damage, such as those often seen in collision damage repair or car paint services. Vehicle bodywork that undergoes significant alterations or repairs may require sensor recalibration to maintain the safety features’ integrity.

Process of Recalibration for Optimal Performance

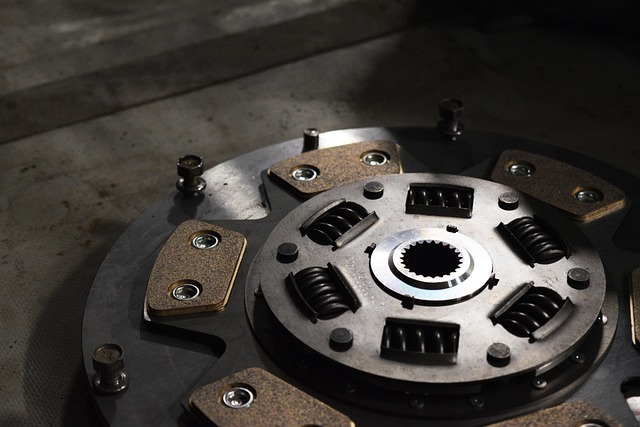

The process of safety sensor recalibration is a meticulous task that requires precision and adherence to Original Equipment Manufacturer (OEM) specifications for optimal performance. It involves adjusting and fine-tuning sensors responsible for detecting critical safety parameters, such as collision forces, impact angles, and vehicle dynamics. This intricate procedure ensures that the sensors provide accurate data, enabling effective activation of safety systems during emergencies.

Automotive repair experts employ specialized tools to calibrate these sensors, simulating real-world scenarios to ensure their reliability. The process includes adjusting sensor sensitivity, response times, and offset values based on OEM guidelines. Regular recalibration is essential for maintaining the integrity of the vehicle’s safety features, especially in the event of an accident or prolonged use, ensuring that the car repair shop’s services meet the highest standards required in the autobody repairs industry.

Ensuring Accuracy: Regular Calibration Checks

Regular calibration checks are an indispensable aspect of maintaining safety sensor accuracy, especially within the automotive industry. As vehicles age or undergo repairs, including dent repair or hail damage repair, the integrity of sensors crucial for safety systems can be compromised. Therefore, routine recalibration ensures that these sensors function optimally and meet Original Equipment Manufacturer (OEM) specifications.

By scheduling periodic calibration tests, car body repair technicians can detect any drift in sensor readings due to environmental factors, wear, or previous repairs. This proactive approach prevents potential hazards associated with inaccurate safety sensors, which could lead to costly dent repair or more severe damage prevention measures.

Safety sensor recalibration is a vital process to ensure optimal performance and meet Original Equipment Manufacturer (OEM) specifications. By understanding the standards, following a meticulous recalibration procedure, and conducting regular calibration checks, manufacturers can guarantee the accuracy and reliability of their safety sensors. This proactive approach not only enhances operational efficiency but also contributes to the overall safety of various industries, making safety sensor recalibration an indispensable practice in maintaining high-quality standards.