Safety sensor recalibration is crucial after car repairs, especially body work, to ensure advanced driver-assistance systems (ADAS) function correctly and safely. Disruptions during repairs can misalign or affect readings of radar, lidar, and camera sensors, impacting ADAS features like collision avoidance and lane-keeping assist. Recalibration adjusts sensor settings for optimal performance and safety on the road.

Safety sensors are critical components in modern machinery, ensuring operations run smoothly and hazards are averted. When these sensors undergo repairs, their accuracy can be compromised. This article delves into the significance of safety sensor recalibration post-repairs to restore optimal performance. Understanding how these sensors function and the impact of repairs on their accuracy is essential. By recalibrating, manufacturers can maintain the integrity of their systems, ensuring both efficiency and worker safety.

- Understanding Safety Sensor Functions

- Impact of Repairs on Sensor Accuracy

- Recalibration: Restoring Optimal Performance

Understanding Safety Sensor Functions

Safety sensors are crucial components in modern vehicles, designed to protect both passengers and other road users. These sensors play a vital role in advanced driver-assistance systems (ADAS) such as collision avoidance, lane departure warning, and adaptive cruise control. They constantly monitor the vehicle’s surroundings, using technologies like radar, lidar, and cameras to detect potential hazards. When issues arise, such as after repairs or maintenance involving auto repair services or car paint services, safety sensor recalibration becomes essential.

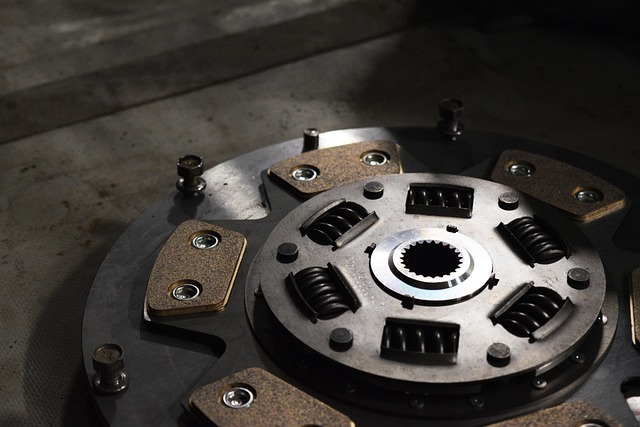

Proper functioning of these sensors relies on accurate readings and precise data. Any disruption caused by repairs, especially complex dent repair procedures, can alter the sensor’s calibration. Over time, environmental factors like temperature changes, wear and tear, or even subtle adjustments during routine servicing can impact their performance. Safety sensor recalibration ensures that these devices remain reliable, providing accurate data to enable the ADAS systems to function optimally.

Impact of Repairs on Sensor Accuracy

When a vehicle undergoes repairs, especially complex ones like those in an auto body shop or Mercedes Benz repair center, it can significantly impact the accuracy and reliability of safety sensors. These sensors play a critical role in modern cars’ advanced driver-assistance systems (ADAS), ensuring the vehicle operates safely on the road.

Repairs that involve structural changes, replacement of components, or adjustments to the vehicle’s sensor network might cause slight misalignments or variations in readings. Over time, these minor discrepancies can accumulate and affect the overall performance and precision of safety sensors, such as those used for collision avoidance, lane-keeping assist, or adaptive cruise control. Therefore, it’s essential to perform a thorough safety sensor recalibration post-repairs to ensure optimal functionality and mitigate potential risks on the road.

Recalibration: Restoring Optimal Performance

After a car collision repair or extensive car body repair, safety sensor recalibration is essential to restoring optimal performance. Automotive body shops often utilize sophisticated sensors and systems to ensure vehicles are safe on the road. These sensors, which can include impact airbags, brake systems, and more, require precise calibration to function correctly. During repairs, these sensors may have been disturbed or compromised, leading to potential safety risks if not recalibrated properly.

Recalibration involves adjusting the sensor’s settings and parameters back to their original specifications, ensuring they accurately detect and respond to various driving conditions. This process is crucial in an automotive body shop’s post-repair procedures, as it verifies that every component functions seamlessly and effectively. By restoring optimal performance, safety sensor recalibration guarantees the vehicle’s safety features operate at peak efficiency, providing drivers with peace of mind on the road.

Regular safety sensor recalibration is paramount after any repair, as it ensures these critical systems function at peak accuracy. By restoring optimal performance, recalibration mitigates potential risks and maintains a safe environment, especially in industrial settings where precise sensor readings are non-negotiable. Prioritizing this maintenance step is a game-changer, ensuring the reliability and efficiency of safety protocols.