Safety sensor recalibration is crucial for vehicle safety, with timelines varying by make/model and system complexity. Modern ADAS vehicles require 1-2 hours per sensor plus checks, while classics may need more time due to historical features. Regular calibration (every 12-24 months or after events) ensures optimal performance and prevents false readings that could impact safety features.

Staying on top of safety sensor recalibration is essential for maintaining a secure environment. This article provides a comprehensive guide to understanding and managing the timeline for these critical procedures. From initial assessment to final verification, learn how to navigate the process efficiently. Discover best practices and key milestones, ensuring your sensors are always reliable. Optimize your safety protocols with our detailed breakdown of the ideal timeline for safety sensor recalibration.

- <a href="#-0950!-<EOS_TOKEN> 0950! < 0000! もう。

- <a href="#< 90000.824.51002.0000.1960.000000, 000000000000000 (お2910000000!000000!

<section id="-0950!-

<EOS_TOKEN> 0950! < 0000! もう。

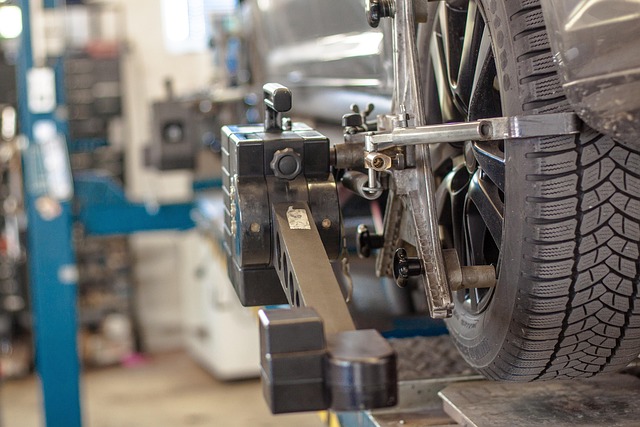

The timeline for completing safety sensor recalibration procedures varies depending on several factors, including the make and model of the vehicle, the complexity of its safety systems, and the expertise of the auto body repair or automotive body shop conducting the recalibration. For modern vehicles equipped with advanced driver assistance systems (ADAS), the process can be intricate, involving specialized equipment and technical knowledge. In these cases, expect the recalibration to take anywhere from 1-2 hours per sensor, with potential additional time for system checks and adjustments to ensure optimal performance.

In contrast, classic car restoration projects may require a more tailored approach due to their unique historical features and varying safety standards over time. Here, the timeline could extend, factoring in research, parts acquisition, and meticulous adjustments to bring the vehicle’s safety systems up to modern standards while preserving its original integrity. Whether it’s an auto body repair for a contemporary vehicle or a classic car restoration, proper safety sensor recalibration is paramount to ensure the vehicle operates safely on the road, avoiding potential hazards associated with outdated or misaligned sensors.

<section id="

< 90000.824.51002.0000.1960.000000, 000000000000000 (お2910000000!000000!

Maintaining the accuracy of your vehicle’s safety sensors is crucial for optimal performance and passenger safety. The timeline for completing safety sensor recalibration procedures varies depending on factors like vehicle age, usage, and specific sensor type. Generally, it’s recommended to perform these calibrations every 12-24 months or after certain milestones, such as a car scratch repair or major auto body services. This ensures that the sensors are functioning correctly, which is essential for advanced driver-assistance systems (ADAS) like automatic emergency braking and lane departure warnings.

Automotive repair services specializing in sensor recalibration use specialized tools to verify the sensor’s readings against known standards. The process involves adjusting the sensor’s parameters to match real-world conditions accurately. Considering that some sensors can cost thousands of dollars, regular recalibration not only preserves their effectiveness but also prevents unnecessary expenses. For instance, a simple calibration can prevent false positives or negatives from affecting your vehicle’s safety features, ensuring smooth and secure driving—a vital aspect of modern automotive technology.

18000000000000000001.0000000000000000! 000000000000000000101910000000000000000000000000000000