Safety sensor recalibration is critical for maintaining accurate and reliable data in vehicles, ensuring advanced driver-assistance systems (ADAS) and autonomous driving capabilities function optimally. Regular manual calibration in industrial settings prevents sensor drift, especially after extreme conditions, crucial for precise measurements like vehicle paint repair and body work. High-quality tools from reputable manufacturers enhance precision, reliability, save resources, and ultimately safeguard customers, contributing to improved road safety.

In the realm of precision sensing, maintaining accuracy is paramount. Sensor drift—a subtle yet significant degradation over time—can compromise data integrity and lead to critical errors in various applications. This article explores the importance of calibration tools in ensuring safe and reliable sensor recalibration. We delve into understanding sensor drift, identifying when manual recalibration is necessary, and selecting the right tools for optimal safety and performance.

- Understanding Sensor Drift and Its Impact

- When Manual Recalibration is Necessary

- Choosing the Right Calibration Tools for Safety

Understanding Sensor Drift and Its Impact

Sensor drift is a common issue that can significantly impact the accuracy and reliability of safety sensors in vehicles. Over time, these sensors, which play a critical role in advanced driver-assistance systems (ADAS) and autonomous driving, may become less precise due to various factors like temperature changes, wear and tear, and environmental influences. Even minor drifts in sensor readings can lead to critical errors in systems designed to prevent auto collisions and ensure the safety of passengers and pedestrians.

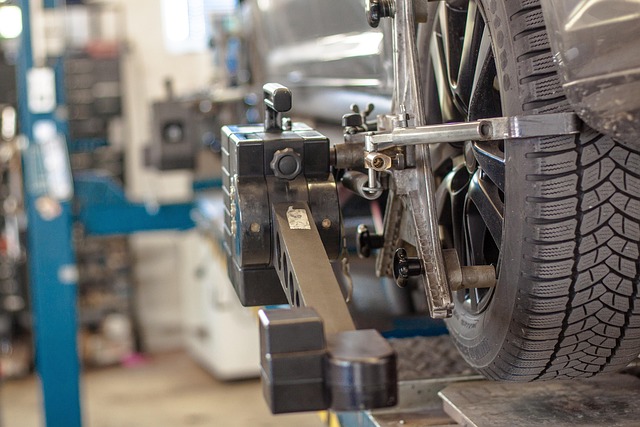

Regular safety sensor recalibration is essential to counteract this drift and maintain optimal performance. Recalibration involves adjusting and fine-tuning the sensors to ensure they provide accurate data, which is crucial for functions like adaptive cruise control, lane-keeping assist, and automatic emergency braking. By addressing sensor drift promptly, auto collision centers can help in maintaining the integrity of car bodywork and frame straightening operations, ultimately contributing to safer driving experiences.

When Manual Recalibration is Necessary

In many industrial settings, regular safety sensor recalibration is non-negotiable. Manual recalibration becomes necessary when sensors have been in continuous operation for extended periods or following specific events like exposure to extreme environmental conditions, physical impacts, or chemical leaks. These external factors can cause a drift in the sensor’s readings, leading to inaccuracies that could compromise safety protocols. For instance, in vehicle paint repair and automotive body work environments, where precise measurements are crucial, regularly calibrating sensors ensure that the dent removal process is safe and effective.

Manual recalibration involves careful procedures to restore the sensor’s accuracy. This often includes comparing the sensor’s output against known standards or using specialized calibration tools designed for that specific sensor type. Such tools enable technicians to fine-tune the sensor’s settings, accounting for any discrepancies caused by wear, tear, or environmental influences, thereby enhancing the overall reliability of safety systems in automotive body work and other critical applications.

Choosing the Right Calibration Tools for Safety

When selecting calibration tools for safety sensor recalibration, it’s paramount to prioritize precision and reliability. The impact of inaccurate recalibration can be severe, leading to potential car collision repair or even worse—the difference between a minor automotive repair and a major, costly incident. Therefore, investing in high-quality tools from reputable manufacturers is crucial. These tools ensure that sensors are accurately adjusted, enhancing the safety features of vehicles during every journey.

Choosing the right set of calibration tools can streamline the process for car repair services, saving time and resources while ensuring customer safety. Moreover, understanding the specific requirements of different sensor types—like those in modern automotive systems—is essential. This way, you can select tools designed to cater to the unique needs of each component, whether it’s for brake systems, airbag deployment mechanisms, or advanced driver-assistance systems (ADAS), all contributing to a seamless car repair process and improved road safety.

Regular sensor recalibration, especially with appropriate calibration tools, is vital for maintaining accurate data and ensuring safety in various industries. By understanding sensor drift and its impact, knowing when manual recalibration is necessary, and selecting the right tools, organizations can enhance operational efficiency and mitigate potential risks associated with inaccurate sensor readings. This proactive approach to safety sensor recalibration is a game-changer in today’s data-driven world.